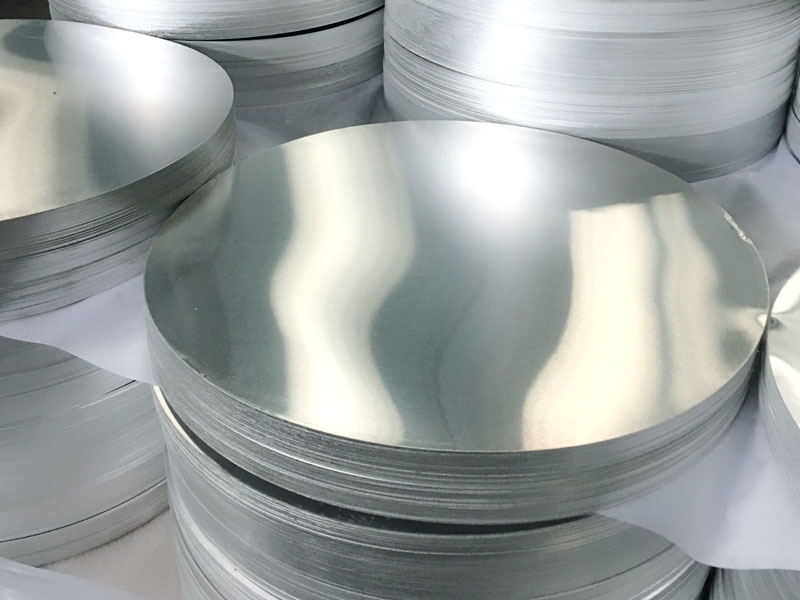

Aluminum Plate

An aluminum plate is a flat, rigid material made from aluminum, a lightweight, corrosion-resistant metal. It is commonly used in construction, manufacturing, and aerospace industries due to its strength-to-weight ratio. Aluminum plates are versatile, available in various thicknesses, and can be easily machined, welded, or formed into different shapes. They offer excellent resistance to rust, making them ideal for outdoor or marine applications. Aluminum plates are used in applications ranging from structural components to decorative finishes, often for their aesthetic appeal and durability. Their ability to conduct heat and electricity also makes them useful in heat exchangers and electrical systems.

Table of Content

Aluminium 2014 Circles

Aluminium alloy is used to create these Aluminium 2014 circles, which are blended with other metals such as Zinc, Silicon, Copper, Tin, and Manganese. Aluminium 2014 Circle is light in weight and has excellent corrosion resistance in all types of hazardous environments. It also protects against acidic environments. These 2014 circles feature excellent toughness, strength, weldability, machinability, malleability, and a variety of other outstanding characteristics. This alloy can also tolerate a wide range of temperatures, from mild to high, in a variety of situations. Due to its structure, Alloy 2014 circular has excellent formability and is slip-resistant.

Aluminium Alloy 2014 Circles Equivalent Grades

| European Standard | BS (OLD) | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) | IS | Canadian |

| EN AW-2014 | HE15 | 3.1255 | A92014 | AlCu4SiMg | 2014 | AlCuSiMn | 24345 | B26S |

ASTM B209 Aluminium Alloy 2014 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : O, T3,T4, T6, T651

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 2014 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 2014 Circle

Aluminium Alloy 2017 Circles

Aluminum 2017 is a high-strength, heat-treatable alloy primarily used in aerospace and military applications. It contains 3.8% - 4.9% copper, offering excellent tensile strength of 470 - 570 MPa and yield strength of 380 - 460 MPa. This alloy is particularly strong but has lower corrosion resistance compared to other alloys like 6061 due to its copper content. Common temper forms include T6 (solution heat-treated and aged) and T3 (solution heat-treated and cold worked). It is used in structural parts, aircraft skins, and military vehicles. Protective coatings are often applied to enhance corrosion resistance in harsh environments.

Aluminium 2017 Circles Equivalent Grades

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4MgSi | AU4G | 3.1325 | A92017 | AlCu4SiMg | 2017 | AlCuMg1 |

ASTM B209 Aluminium Alloy 2017 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : O, T3,T4, T6, T651

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 2017 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 2017 Circle

Aluminium Alloy 2024 Circles

Aluminium 2024 Circles Some of the qualities are high tensile strength, good dimensional precision, superior surface finishes, strong construction, long functioning, good fatigue resistance, good weldability, good machinability, corrosion resistance, anti-corrosive body, and withstands at various temperatures. This material can only be fused by friction welding and has an average machinability. The alloying materials used in the 2024 aluminium alloy Circles considerably boost its strength. Copper (Cu), magnesium (Mg), and manganese (Mn) are added with a combined elemental percentage of 6.5 percent – Cu-4.4 percent, Mg-1.5 percent, and Mn-0.6 percent – to explain this. The high copper content does lessen the material's corrosion resistance, but it does boost strength. Yield strength, ultimate strength, fatigue strength, shear strength, shear modulus, and modulus of elasticity are a few of the crucial qualities in 2024.

Aluminium 2024 Circles Equivalent Grades

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4Mg1 | AU4G1 | 3.1355 | A92024 | AlCu4Mg1 | 2024 | AlCuMg2 |

ASTM B209 Aluminium Alloy 2024 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : O, T3,T4, T6, T651

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 2024 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 2024 Circle

Aluminium Alloy 6061 Circles

Aluminium Alloy 6061 Circles are made from one of the most useful and often used heat treatable alloys. Excellent machinability, weldability, and medium strength are all displayed by these Aluminium Alloy 6061 Circles. Despite being weaker than the majority of the 2xxx and 7xxx alloys, 6061 is frequently chosen because of its good corrosion resistance in all tempers or because welding or brazing are required. It may be easily cold worked and produced in the annealed condition and has excellent joining properties. Aluminium Alloy 6061 Circles also accept anodizing well.

Aluminium 6061 Circles Equivalent Grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| A96061 | AW-AlMg1SiCu EN AW-6061 |

AlMgSiCu | AlMg1SiCu | HE20 | AA6061 | 3.3211 |

ASTM B209 Aluminium Alloy 6061 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : O, T3,T4,T5, T6, T651 T6511

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 6061 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 6061 Circle

Aluminium Alloy 6063 Circles

These Aluminium Alloy 6061 Circles were designed and developed in accordance with national and international norms and specifications. These Aluminium Alloy 6061 Circles are being meticulously fabricated by our staff using cutting-edge production methods and contemporary equipment. Our professionals oversee each stage and direct our staff to produce the highest calibre items. We Aluminium Alloy 6061 Circles that are easily resistant to corrosive and harsh environments.

Aluminium Alloy 6063 Circles Equivalent Grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| AA6063 | AW-AlMg0,7Si EN AW-6063 |

AlMgSi0.5 | AlMg0,7Si | HE9 | 3.32206 | 3.32206 |

ASTM B209 Aluminium Alloy 6063 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : O, T3,T4, T6, T651

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 6063 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 6063 Circle

Aluminium Alloy 6082 Circles

Due Aluminium 6082 Circle of its corrosion-prone character, this alloy circle is helpful in cryogenic temperatures. Brinell hardness, thermal conductivity, electrical conductivity, elongation, density, melting temperature, modulus of expansion, and elongation are all physical and mechanical characteristics of this alloy circle. Circles made of aluminium 6082 offer great hardness and good corrosion resistance.

Aluminium Alloy 6082 Circles Equivalent Grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| A96082 | AW-6082 | AlMgSi1 | Al Si1MgMn | HE30 | A96082 | 3.2315 |

ASTM B209 Aluminium Alloy 6082 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : O, T3,T4, T6, T651

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 6082 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 6082 Circle

Aluminium Alloy 7075 Circles

Aluminium Alloy 7075 Circles Equivalent Grades

| UNS | EN | DIN,WNr | JIS | AFNOR | ISO | BS | GOST |

| A97075 | ENAW-AlZn5.5MgCu EN AW-7075 |

3.4365 AlZnMgCu1.5 |

7075 | 7075 A-Z5GU | AlZn6MgCu | 7075 L95 L96 | V95 |

ASTM B209 Aluminium Alloy 7075 Circles Specification

Standards : ASTM B209 / ASME SB209

Temper : T3,T4,T5, T6, T651 T6511

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy 7075 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 7075 Circle

Aluminium Alloy HE-9 Circles

Aluminium Circles HE-9 can be used for a wide range of electrical housing, outdoor antennas, and other things after undergoing secondary processing. Additionally, we improve the product quality by using the best raw materials, ensuring that the Aluminium Circles HE-9 meets national criteria Dhanlaxmi Steel Distributors provides circles can produce Aluminium Circles HE-9 in a variety of tempers and it may be customised by customers for size.

Aluminium Alloy HE-9 Circles Equivalent Grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| AA6063 | AW-AlMg0,7Si EN AW-6063 |

AlMgSi0.5 | AlMg0,7Si | HE9 | 3.32206 | 3.32206 |

ASTM B209 Aluminium Alloy HE-9 Circles Specification

Standards : ASTM B209 / ASME SB209

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy HE-9 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum HE-9 Circle

Aluminium Alloy HE-15 Circles

Aluminium Alloy HE-15 Circles Equivalent Grades

| European Standard | BS (OLD) | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) | IS | Canadian |

| EN AW-2014 | HE15 | 3.1255 | A92014 | AlCu4SiMg | 2014 | AlCuSiMn | 24345 | B26S |

ASTM B209 Aluminium Alloy HE-15 Circles Specification

Standards : ASTM B209 / ASME SB209

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy HE-15 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum HE-15 Circle

Aluminium Alloy HE-20 Circles

Aluminium Circles HE-20 have low density and a low unit weight. Additionally, it has a remarkable elongation. Even for items like battery covers that have strict purity requirements, not all aluminium disc circles are certified enough to be satisfactory materials. A significant benefit of Aluminium Circles HE-20 is their high anti-corrosion qualities. Aluminium Circles HE-20 service life is thereby increased and it retains its original colour and surface quality even when employed in specialised industries.

Aluminium Alloy HE-20 Circles Equivalent Grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| A96061 | AW-AlMg1SiCu EN AW-6061 |

AlMgSiCu | AlMg1SiCu | HE20 | AA6061 | 3.3211 |

ASTM B209 Aluminium Alloy HE-20 Circles Specification

Standards : ASTM B209 / ASME SB209

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy HE-20 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum HE-20 Circle

Aluminium Alloy 6082 Circles

Aluminium Alloy HE-30 Circles Equivalent Grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| A96082 | AW-6082 | AlMgSi1 | Al Si1MgMn | HE30 | A96082 | 3.2315 |

ASTM B209 Aluminium Alloy HE-30 Circles Specification

Standards : ASTM B209 / ASME SB209

Thickness : 8 mm to 500 mm

Diameter : 200 mm to 1400 mm/p>

Circle Diameter :3" DIA up to 38" DIA 1500 lbs max

Finish : Mill, Customer specific finish

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Circles

Aluminium Alloy HE-30 Circle Standard Specification

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Circle

ASTM B632 / B632M - Standard Specification for Aluminum-Alloy Rolled Tread Circle

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circle

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circle for Pressure Vessels

AMS 4001 - Aluminum Circles, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Circles, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum HE-30 Circle