Copper Pipes

Due to its longevity, resistance to corrosion, and thermal conductivity, copper pipes are vital components commonly used in hvac, plumbing, and many industrial applications. they are available in a variety of types and sizes to serve diverse purposes. for fluid transport and heat transfer applications, copper pipes are adaptable and trustworthy options.

Specification of Copper Pipes

| Outside Diameter | 4.00 to 150 mm. |

|---|---|

| Copper Pipe Water Line Thickness | 0.25-8mm |

| BS 2871 Copper Pipe Length | 1 to 6 meter (Single /Double Random & Cut Length) |

| Tempers | H, HH, QH, O, Soft Annealed |

| Cu Pipes Type | Light Drawn / Seamless /Bright / Light & Full Annealed /Hard Drawn |

| Copper Alloy EN 1057 Pipes Shape | Rectangular / Square / Rectangular |

| Standards | ASTM B88 /ASTM B280/ ASTM B75/ASTM B68 / JIS H 3300 / BS2871 or EN1057: PART 2:1972 / DIN 8905/ 1754/IS2501, JIS3300-2006, AS/NZS1571 |

| Semi-finished Copper Pipe Specification | ASTM B280,JIS3300-2006, JIS H2300, AS/NZS1571 |

| Straight Copper Pipe Grades | C19400, C1100, C12200, C1220T, C1201T, C10200, TP1, T2, C14200, TP2, C1200, TU2, C1020T etc |

| Life of Copper Pipe | 20-50 years |

| Disadvantages of Copper Pipe | Freeze Easily, Cannot Withstand Acidic Water, Expensive |

| Copper Alloy Pipe Uses | Electrical Applications , Refrigeration ,Water supply |

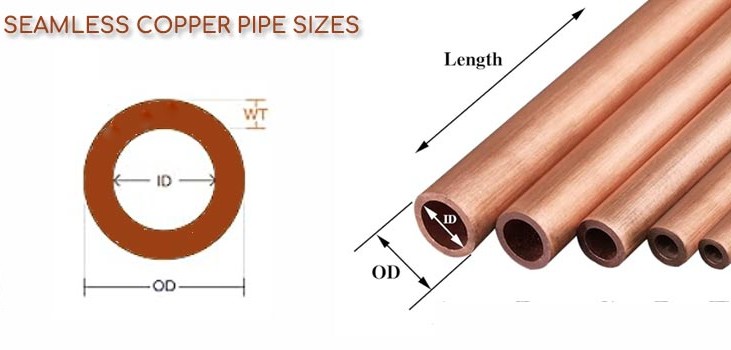

Size Chart Of Seamless Copper Pipe

| Outside diameter (OD) [in (mm)] |

Nominal size |

Inside diameter (ID) [in (mm)] |

||

|---|---|---|---|---|

| Type L | Type K | Type M | ||

| 1⁄2 (12.7) | 3⁄8 | 0.430 (10.922) | 0.402 (10.211) | 0.450 (11.430) |

| 3⁄8 (9.5) | 1⁄4 | 0.315 (8.001) | 0.305 (7.747) | |

| 2 5⁄8 (66.675) | 21⁄2 | 2.465 (62.611) | 2.435 (61.849) | 2.495 (63.373) |

| 5⁄8 (15.875) | 1⁄2 | 0.545 (13.843) | 0.528 (13.411) | 0.569 (14.453) |

| 7⁄8 (22.225) | 3⁄4 | 0.785 (19.939) | 0.745 (18.923) | 0.811 (20.599) |

| 3⁄4 (19.05) | 5⁄8 | 0.668 (16.967) | 0.652 (16.561) | 0.690 (17.526) |

| 1 1⁄8 (28.575) | 1 | 1.025 (26.035) | 0.995 (25.273) | 1.055 (26.797) |

| 1 5⁄8 (41.275) | 11⁄2 | 1.505 (38.227) | 1.481 (37.617) | 1.527 (38.786) |

| 1 3⁄8 (34.925) | 11⁄4 | 1.265 (32.131) | 1.245 (31.623) | 1.291 (32.791) |

| 2 1⁄8 (53.975) | 2 | 1.985 (50.419) | 1.959 (49.759) | 2.009 (51.029) |

| 3 1⁄8 (79.375) | 3 | 2.945 (74.803) | 2.907 (73.838) | 2.981 (75.717) |

Grades of Copper Pipe

| ISO Designation | CEN N0. | British Standard (BS) |

|---|---|---|

| Cu-ETP | CW003A | C101 |

| Cu-ETP1 | CW003A | C100 |

| CuAg(0.07) | CW012A | |

| CuAg(0.04) | CW011A | C101 |

| CuAg(0.10) | CW013A | |

| Cu-HCP | CW021A | |

| Cu-FRHC | CW005A | C102 |

| Cu-DLP | CW023A | |

| CuAs | C105 | |

| Cu-FRTP | CW006A | C104 |

| CuAsP | C107 | |

| Cu-DHP | CW024A | C106 |

| CuAg(0.07P) | CW015A | |

| CuAg(0.04P) | CW014A | |

| CuAg(0.10P) | CW016A | |

| Cu-OFE | CW009A | C110 |

| Cu-OF | CW008A | C103 |

| CuCd1 | C108 | |

| CuCr1Zr | CW106C | CC102 |

| CuCr1 | CW105C | CC101 |

| CuNi2Si | CW111C | CC102 |

| CuNi1Si | CW109C | |

| CuNi3Si | CW112C | |

| CuNiP | CW108C | C113 |

| CuNi4AlSi | ||

| CuBe2 | CW101C | CB101 |

| CuNi2Be | CW110C | |

| CuCo1Ni1Be | CW103C | |

| CuCo2Be | CW104C | C112 |

| CuZr | CW120C | |

| CuSi3Mn1 | CW116C | CS101 |

| CuSi2Mn | CW115C | |

| CuTeP | CW118C | C109 |

| CuPb1P | CW113C | |

| CuSP | CW114C | C111 |

| CuZn0.5 | CW119C | |

| G-CuSn | ||

| Cu-G | CS040A | HCC1 |

| CuCr1-G | CS140C CP140C |

CC1-TF |

| G-CuNi2Si | ||

| G-CuNiP | ||

| G-CuCo2Be |

Why is Copper Used in Water Pipes ?

Copper Gas Pipe Thickness Chart

| (mm) | Outside Diameter (mm) |

Table Y Half hard an annealed tube |

Table X Half hard light gauge tube |

Table Z Hard drawn thin wall tube |

|||

|---|---|---|---|---|---|---|---|

| Maximum Working Pressure (N/mm2) |

Thickness (mm) |

Maximum Working Pressure (N/mm2) |

Thickness (mm) |

Maximum Working Pressure (N/mm2) |

Thickness (mm) |

||

| 8 | 8 | 10.5 | 0.8 | 9.7 | 0.6 | 9.8 | 0.5 |

| 6 | 6 | 14.4 | 0.8 | 13.3 | 0.6 | 11.3 | 0.5 |

| 10 | 10 | 8.2 | 0.8 | 7.7 | 0.6 | 7.8 | 0.5 |

| 15 | 15 | 6.7 | 1 | 5.8 | 0.7 | 5 | 0.5 |

| 12 | 12 | 6.7 | 0.8 | 6.3 | 0.6 | 6.4 | 0.5 |

| 18 | 18 | 5.5 | 1 | 5.6 | 0.8 | 5 | 0.6 |

| 28 | 28 | 4.2 | 1.2 | 4 | 0.9 | 3.2 | 0.6 |

| 22 | 22 | 5.7 | 1.2 | 5.1 | 0.9 | 4.1 | 0.6 |

| 35 | 35 | 4.1 | 1.5 | 4.2 | 1.2 | 3 | 0.7 |

| 54 | 54 | 3.6 | 2 | 2.7 | 1.2 | 2.5 | 0.9 |

| 159 | 159.4 | 1.5 | 2 | 1.5 | 1.5 | ||

| 42 | 42 | 3.4 | 1.5 | 3.5 | 1.2 | 2.8 | 0.8 |

| 67 | 67 | 2.8 | 2 | 2 | 1.2 | 2 | 1 |

| 108 | 108.1 | 2.2 | 2.5 | 1.7 | 1.5 | 1.7 | 1.2 |

| 76.1 | 76.2 | 2.5 | 2 | 2.4 | 1.5 | 1.9 | 1.2 |

| 133 | 133.4 | 1.4 | 1.5 | 1.6 | 1.5 | ||

Most Common Types Cu Pipes

Seamless Copper Pipe

Copper Water Pipe

Copper Gas Pipe

Threadless Copper Pipe

Threaded Copper Pipe

Cu Hard Drawn Pipes

Bright Annealed Copper Pipe

Light Drawn Copper Pipe

Copper Tubes

Copper Tube is one of the Components that is needed in Air Conditioning and Refrigerant System. The Tube is used as a path for the Refrigerant to flow between System Components and to Contain it from escaping to the atmosphere. Sizing, Installation Layout and Fittings must be done Properly to ensure that the System runs efficiently.

During Installation, it is of utmost Importance that Moisture, Dirt and other Contaminants are Prevented from entering the System. These foreign particles will affect the Performance of the System and may even cause damage to some of the Components.

During the production of the Copper Tube, the inside of the Tube has been Cleaned and Dried before being sealed at both ends to ensure that it remains that way. You must check to make sure that the Refrigerant that is going to be used does not react with the Copper. Ammonia refrigerant will react with Copper hence it should not be used Instead.

| Standard | Symbol |

|---|---|

| ASTM B 68 | C 12200 |

| ASTM B 75 | DLP C 12000 |

| BS 2871 Part 2 | C 101 |

| BS 2871 Part 3 | C 106 |

| EN 12451 | DHP |

| JIS H 3300 | C 1220 |

| IS 2501 | ETP Copper |