Plastic Mould Steel

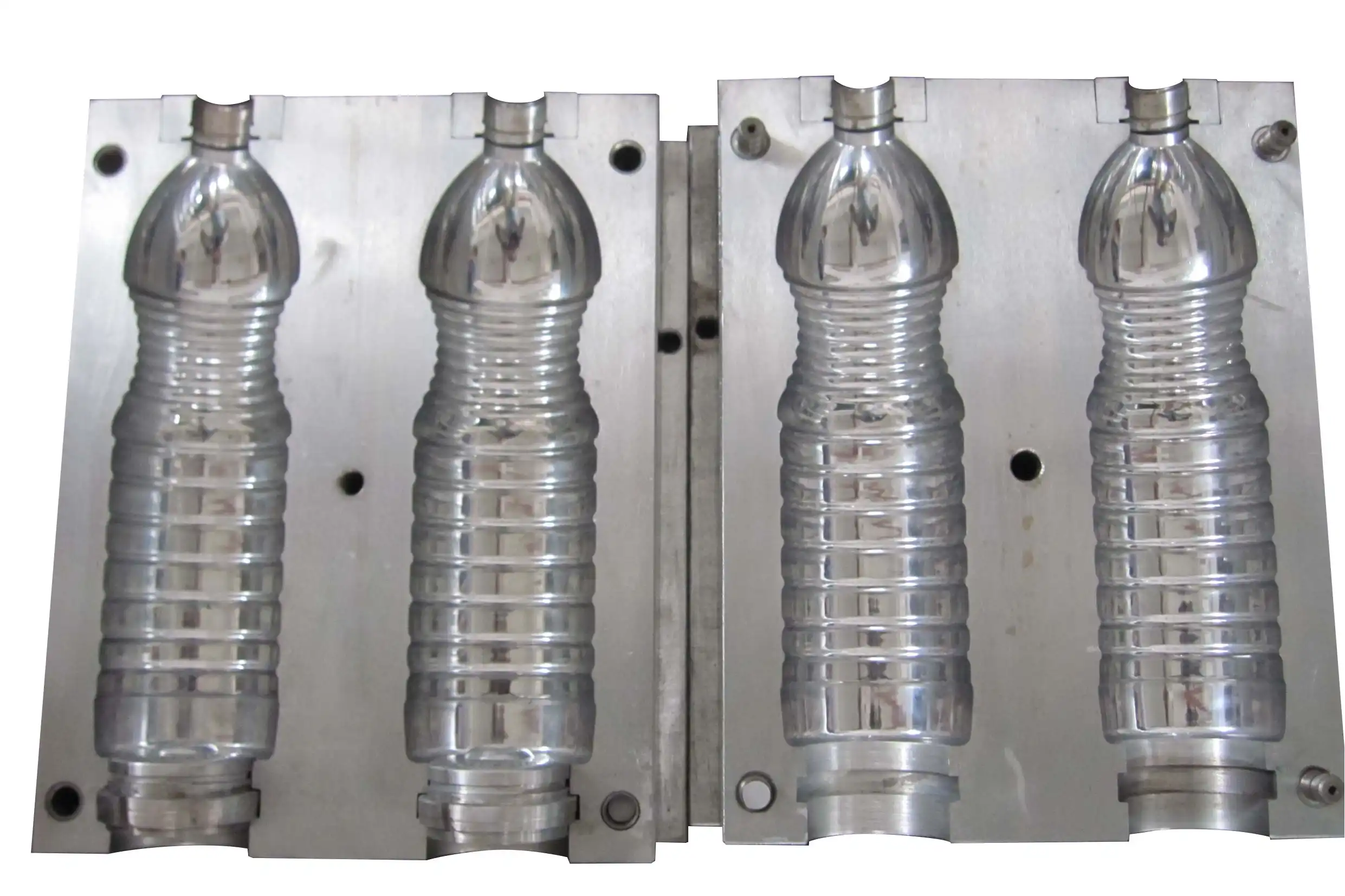

P-type or 'plastic mould steel' are classified with the prefix 'P' and are designed to be suitable for plastic injection moulding dies and zinc die casting. Plastic mould steel supplier provides materials that are characterised by good dimensional stability during heating, good polishability, high impact strength and good wear characteristics.

Product Specification

| MATERIAL | CHEMISTRY | Application | ||||||||||||||

| TG | AISI/ASTM | EN | DIN | JIS | C | S | P | SI | Mn | Cr | V | W | Mo | Ni | Ai | |

| TGP-40 | P20+Ni | ISO 4957 | DIN 1.2738 & DIN 1.2738HH | 0.35- 0.45 |

≤0.030 | ≤0.030 | 0.20- 0.40 |

1.30- 1.60 |

1.80- 2.10 |

0.15- 0.25 |

0.90- 1.20 |

injection and thermoplastic extrusion moulds, rubber moulds and more | ||||

| TGP-50 | 0.42 | ≤0.005 | ≤0.03 | ≤1.00 | ≤1.00 | 13.5 | Production of PVC molds, Long-life molds, Molds for disposable tableware, Production of optics parts | |||||||||

| TGP-80 | P21 | NAK80 | 0.15 | ≤0.003 | ≤0.025 | ≤0.45 | 1.55 | 1 | 0.35 | 3.1 | 0.95 | Mirror Plastic Moulds, transparent plastic moulds, moulds for optical instruments, medical devices | ||||

| TGP-136 | 0.4 | ≤0.015 | ≤0.03 | 1.05 | 0.55 | 13.5 | 0.3 | 0.3 | 0.22 | mirro plastic moulds, moulds for optical lens, high resisting moulds, | ||||||

| PHX Supra | 1.2316 | 0.15 | 15 | 3.5 | 4.5 | molds for the processing of corrosion plastics | ||||||||||

Chemical composition:

|

CARBON C % |

SILICON Si% |

MANGANESE Mn% |

CHROMIUM Cr% |

MOLYBDENUM Mo% |

NICKEL Ni% |

SULPHUR |

PHOSPHORUS P% |

|

|

1.2311 |

0.35-0.45 |

0.20-0.40 |

1.3O-1.60 |

1.8-2.10 |

0.15-0.25 |

- |

≤ 0.035% |

≤ 0.035% |

|

1.2312 |

0.35-0.45 |

0.30-0.50 |

1.4O-1.60 |

1.8-2.10 |

0.15-0.25 |

≤ 0.035% |

≤ 0.035% |

|

|

1.2738 |

0.35-0.45 |

0.20-0.40 |

1.3O-1.60 |

1.8-2.10 |

0.15-0.25 |

0.9-1.2 |

≤ 0.03% |

≤ 0.03% |

|

1.2316 |

0.33-0.43 |

1.00% MAX |

1.50% MAX |

15.5-17.5 |

0.8O-1.30 |

≤ 1.00% |

≤ 0.03% |

≤ 0.03% |

|

1.2083 |

0.36-0.46 |

1.00% MAX |

1.00% MAX |

12.5-14.5 |

≤ 0.03% |

≤ 0.03% |

|

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

GERMANY |

SLOVANIA |

ITALY |

JAPAN |

S.KOREA |

TAIWAN |

CHEZ. |

CHINA |

AMERICAN |

||||||

|

MOULD |

VILLARES |

BOHLER |

AASAB |

BUDERUS |

DEW |

GRODITZ |

RAVNE |

LUCCHINI |

VARONA |

DAIDO |

HITACHI |

NIPPON |

SANYO |

DOOSAN |

GLORIA |

POLDI |

EST |

AISI |

|

1.2311 |

VP20ISOF |

M202 |

618 |

ISO-BM |

1.2311 |

1.2311 |

UTOPNEX |

KEYLOS2311 |

- |

HPM7 |

KPM30 |

PCM40 |

HP4A |

GMP20[ESR] |

GS3D |

YTJ20A |

P-20 |

|

|

1.2312 |

VP20ISOFS |

- |

HOLDAX |

- |

1.2312 |

- |

UTOP N |

KEYLOS2312 |

- |

- |

- |

PCM40S |

- |

GS3S |

- |

P-20+Su |

||

|

1.2738 |

VP20ISO |

M238 |

IMPAX SUPREME |

ISO-BM |

1.2738 |

1.2738 |

UTOPNIN |

KEYLOS2738 |

- |

HPM |

- |

- |

- |

GMP20+Ni [ESR] |

LDHN |

YTJ21 |

P-20Ni |

|

|

1.2316 |

- |

M300 |

RAMAX S |

ISO-B |

1.2316 |

1.2316 |

PK335 |

KEYLOS2316 |

UPS3 |

HPM77 |

- |

- |

- |

1.2316 [ESR] |

- |

YTG173 |

420 |

|

|

1.2085 |

- |

- |

- |

- |

1.2085 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

420 |

||

|

1.2083 |

VP420IM |

M310 |

STAVAX |

ISO-B |

1.2083 |

1.2083 VICTORY |

PK4EX |

KEYLOS2083 |

- |

S-STAR |

HPM38 |

- |

SUS420J2 |

HEMS1A |

GMP420 [ESR] |

AK4R |

YTG136 |

420 |

1.2311

Equivalent grades:

|

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

GERMANY |

SLOVANIA |

ITALY |

JAPAN |

S.KOREA |

TAIWAN |

CHEZ. |

CHINA |

AMERICAN |

||||||

|

MOULD |

VILLARES |

BOHLER |

AASAB |

BUDERUS |

DEW |

GRODITZ |

RAVNE |

LUCCHINI |

VARONA |

DAIDO |

HITACHI |

NIPPON |

SANYO |

DOOSAN |

GLORIA |

POLDI |

EST |

AISI |

|

1.2311 |

VP20ISOF |

M202 |

618 |

ISO-BM |

1.2311 |

1.2311 |

UTOPNEX |

KEYLOS2311 |

- |

HPM7 |

KPM30 |

PCM40 |

HP4A |

GMP20[ESR] |

GS3D |

YTJ20A |

P-20 |

|

Alloyed and pre-toughened tool steel, especially suitable for polishing; high dimensional stability.

| 1.2311 ROUND BAR |

1.2311 FLAT BAR |

1.2311 SQUARE

|

1.2311 PLATE / SHEETS |

1.2311 FORGED BARS

|

1.2311 ROLLED BARS

|

1.2311 PEELED or 1.2311 BRIGHT

|

Application:

Moulding plates, inserts and high-tensile machine parts

Chemical Composition:

|

|

CARBON C % |

SILICON Si% |

MANGANESE Mn% |

CHROMIUM Cr% |

MOLYBDENUM Mo% |

NICKEL Ni% |

SULPHUR |

PHOSPHORUS P% |

|

1.2311 |

0.35-0.45 |

0.20-0.40 |

1.3O-1.60 |

1.8-2.10 |

0.15-0.25 |

- |

≤0.035% |

≤0.035% |

|

Annealing |

710 - 730°C |

||||||||||

|

Hardness after annealing |

Max. 230 HB |

||||||||||

|

Stress relieving |

Approx 650°C |

||||||||||

|

Hot forming |

1050 - 850°C |

||||||||||

|

Hardening |

870 - 890°C |

||||||||||

|

Quenching media |

Oil, Salt bath,vacuum |

||||||||||

|

Hardness after quenching |

50 - 54 HRC |

||||||||||

|

Hardness after tempering :

|

|

1.2312

Equivalent grades:

|

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

GERMANY |

SLOVANIA |

ITALY |

JAPAN |

S.KOREA |

TAIWAN |

CHEZ. |

CHINA |

AMERICAN |

||||||

|

MOULD |

VILLARES |

BOHLER |

AASAB |

BUDERUS |

DEW |

GRODITZ |

RAVNE |

LUCCHINI |

VARONA |

DAIDO |

HITACHI |

NIPPON |

SANYO |

DOOSAN |

GLORIA |

POLDI |

EST |

AISI |

|

1.2312 |

VP20ISOFS |

- |

HOLDAX |

- |

1.2312 |

- |

UTOP N |

KEYLOS2312 |

- |

- |

- |

PCM40S |

- |

|

GS3S |

- |

P-20+Su |

|

Alloyed and pre-toughened tool steel acquires the property of excellent machinability in the hardened condition because of the Sulphur additive. It thus results into high dimensional stability. Compared to 1.2311 grade in 1.2312, 30% increase in milling speed and 300% increase in drilling speed can be expected. But 1.2312 is not suitable for polishing requirements.

Plastic injection mould cores and cavities, extursion dies for thermoplastics (PE, PP, PS), thermosetting plastics, transparent melts.

| 1.2312 ROUND BAR |

1.2312 FLAT BAR |

1.2312 SQUARE

|

1.2312 PLATE / SHEETS |

1.2312 FORGED BARS

|

1.2312 ROLLED BARS

|

1.2312 PEELED or 1.2311 BRIGHT

|

Application:

Plates for mould tools and dies with increased requirements on strength; high-tensile machine parts

Chemical composition:

|

|

CARBON C % |

SILICON Si% |

MANGANESE Mn% |

CHROMIUM Cr% |

MOLYBDENUM Mo% |

NICKEL Ni% |

SULPHUR |

PHOSPHORUS P% |

|

1.2312 |

0.35-0.45 |

0.30-0.50 |

1.4O-1.60 |

1.8-2.10 |

0.15-0.25 |

|

≤0.035% |

≤0.035% |

Heat Treatment:

|

Annealing |

710 - 730°C |

||||||||||

|

Hardness after annealing |

Max. 230 HB |

||||||||||

|

Stress relieving |

Approx 650°C |

||||||||||

|

Hot forming |

1050 - 850°C |

||||||||||

|

Hardening |

870 - 890°C |

||||||||||

|

Quenching media |

Oil, Salt bath,vacuum |

||||||||||

|

Hardness after quenching |

50 - 54 HRC |

||||||||||

|

Hardness after tempering :

|

|

1.2316

Equivalent grades:

|

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

GERMANY |

SLOVANIA |

ITALY |

JAPAN |

S.KOREA |

TAIWAN |

CHEZ. |

CHINA |

AMERICAN |

||||||

|

MOULD |

VILLARES |

BOHLER |

AASAB |

BUDERUS |

DEW |

GRODITZ |

RAVNE |

LUCCHINI |

VARONA |

DAIDO |

HITACHI |

NIPPON |

SANYO |

DOOSAN |

GLORIA |

POLDI |

EST |

AISI |

|

1.2316 |

- |

M300 |

RAMAX S |

ISO-B |

1.2316 |

1.2316 |

PK335 |

KEYLOS2316 |

UPS3 |

HPM77 |

- |

- |

- |

1.2316 [ESR] |

- |

YTG173 |

420 |

|

Corrosion resistant, high-alloy, polishable, pre-toughened tool stee

| 1.2316 ROUND BAR |

1.2316 FLAT BAR |

1.2316 SQUARE

|

1.2316 PLATE / SHEETS |

1.2316 FORGED BARS

|

1.2316 ROLLED BARS

|

1.2316 PEELED or 1.2311 BRIGHT

|

Application:

Moulds for processing corrosive plastics.

Chemical Composition:

|

|

CARBON C % |

SILICON Si% |

MANGANESE Mn% |

CHROMIUM Cr% |

MOLYBDENUM Mo% |

NICKEL Ni% |

SULPHUR |

PHOSPHORUS P% |

|

1.2316 |

0.33-0.43 |

1.00% MAX |

1.50% MAX |

15.5-17.5 |

0.8O-1.30 |

≤1.00% |

≤0.03% |

≤0.03% |

Heat Treatment:

|

Annealing |

810 - 830°C |

||||||||||

|

Hardness after annealing |

Max. 235 HB |

||||||||||

|

Stress relieving |

Approx 650°C |

||||||||||

|

Hot forming |

1050 - 850°C |

||||||||||

|

Hardening |

1020 - 1040°C |

||||||||||

|

Quenching media |

Oil, Salt bath,vacuum |

||||||||||

|

Hardness after quenching |

48 - 52 HRC |

||||||||||

|

Hardness after tempering :

|

|

1.2378

Equivalent grades:

|

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

GERMANY |

SLOVANIA |

ITALY |

JAPAN |

S.KOREA |

TAIWAN |

CHEZ. |

CHINA |

AMERICAN |

||||||

|

MOULD |

VILLARES |

BOHLER |

AASAB |

BUDERUS |

DEW |

GRODITZ |

RAVNE |

LUCCHINI |

VARONA |

DAIDO |

HITACHI |

NIPPON |

SANYO |

DOOSAN |

GLORIA |

POLDI |

EST |

AISI |

|

1.2738 |

VP20ISO |

M238 |

IMPAX SUPREME |

ISO-BM |

1.2738 |

1.2738 |

UTOPNIN |

KEYLOS2738 |

- |

HPM |

- |

- |

- |

GMP20+Ni [ESR] |

LDHN |

YTJ21 |

P-20Ni |

|

Low-sulphur tool steel is supplied in pre-toughened condition. Due to its nickel content, it features uniform strength even with maximum plate dimensions.

| 1.2378 ROUND BAR |

1.2378 FLAT BAR |

1.2378 SQUARE

|

1.2378 PLATE / SHEETS |

1.2378 FORGED BARS

|

1.2378 ROLLED BARS

|

1.2378 PEELED or 1.2311 BRIGHT

|

Application:

Large cavity plates with deep cavities for items such as bumpers, dashboards, moulding frames.

Chemical composition:

|

|

CARBON C % |

SILICON Si% |

MANGANESE Mn% |

CHROMIUM Cr% |

MOLYBDENUM Mo% |

NICKEL Ni% |

SULPHUR |

PHOSPHORUS P% |

|

1.2738 |

0.35-0.45 |

0.20-0.40 |

1.3O-1.60 |

1.8-2.10 |

0.15-0.25 |

0.9-1.2 |

≤0.03% |

≤0.03% |

Heat Treatment:

|

Annealing |

710 - 730°C |

||||||||||

|

Hardness after annealing |

Max. 240 HB |

||||||||||

|

Stress relieving |

Approx 650°C |

||||||||||

|

Hot forming |

1050 - 850°C |

||||||||||

|

Hardening |

870 - 890°C |

||||||||||

|

Quenching media |

Oil, Salt bath,vacuum |

||||||||||

|

Hardness after quenching |

50 - 54 HRC |

||||||||||

|

Hardness after tempering :

|

|

1.2083

Equivalent grades:

|

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

GERMANY |

SLOVANIA |

ITALY |

JAPAN |

S.KOREA |

TAIWAN |

CHEZ. |

CHINA |

AMERICAN |

||||||

|

MOULD |

VILLARES |

BOHLER |

AASAB |

BUDERUS |

DEW |

GRODITZ |

RAVNE |

LUCCHINI |

VARONA |

DAIDO |

HITACHI |

NIPPON |

SANYO |

DOOSAN |

GLORIA |

POLDI |

EST |

AISI |

|

1.2083 |

VP420IM |

M310 |

STAVAX |

ISO-B |

1.2083 |

1.2083 VICTORY |

PK4EX |

KEYLOS2083 |

- |

S-STAR |

HPM38 |

- |

SUS420J2 |

HEMS1A |

GMP420 [ESR] |

AK4R |

YTG136 |

420 |

Properties like Low corrosion, high-alloy, low warpage steel for through hardening with excellent properties for mirror polishing as well as good photoetching, good machinability, high wear resistance and high dimensional stability is expected from this steel.

| 1.2083 ROUND BAR |

1.2083 FLAT BAR |

1.2083 SQUARE

|

1.2083 PLATE / SHEETS |

1.2083 FORGED BARS

|

1.2083 ROLLED BARS

|

1.2083 PEELED or 1.2311 BRIGHT

|

Application:

Mould plates and inserts for working with chemically aggressive plastics; because of excellent polishing, suitable for optical and medical products

Chemical Composition:

|

|

CARBON C % |

SILICON Si% |

MANGANESE Mn% |

CHROMIUM Cr% |

MOLYBDENUM Mo% |

NICKEL Ni% |

SULPHUR |

PHOSPHORUS P% |

|

1.2083 |

0.36-0.46 |

1.00% MAX |

1.00% MAX |

12.5-14.5 |

|

|

≤0.03% |

≤0.03% |

Heat Treatment:

|

Annealing |

810 - 830°C |

||||||||||

|

Hardness after annealing |

Max. 230 HB |

||||||||||

|

Stress relieving |

Approx 650°C |

||||||||||

|

Hot forming |

1050 - 850°C |

||||||||||

|

Hardening |

870 - 990°C |

||||||||||

|

Quenching media |

Oil, Salt bath,vacuum |

||||||||||

|

Hardness after quenching |

52 - 56 HRC |

||||||||||

|

Hardness after tempering :

|

|

|

Steel Classification |

Standard |

|

Assab |

Bohler |

Edelstahl |

Thyssen |

Hitachi |

||

|

DIN |

JIS |

AISI |

|||||||

|

Plastic Mould Steel |

1.1203 |

SUS 420 J2 |

1055 |

|

- |

- |

- |

CK 55 |

SCS 2 |

|

1.2311 |

P20 |

|

718 |

W330 |

2311 iso BM |

2311 |

|||

|

1.2312 |

P20+S |

|

Holdax |

M200 |

2312 |

2312 |

|||

|

1.2738 |

P20+Ni |

|

Impax |

- |

- |

2738 |

|||

|

1.2316 |

- |

|

RaMaxS |

M300 |

- |

2316 |

|||

|

1.2083 |

420 |

|

Stavax |

M310 |

2083 |

2083 |

|||

|

1.2085 |

420+S |

|

- |

M304 |

21 MnCr 5 |

- |

|||

|

1.2162 |

- |

|

Prexi |

M100 |

- |

2162 |

|||

|

|

|||||||||

|

Hot Work Steel |

1.2344 |

SKD 61 |

H13 |

|

8407 |

W302 |

2344 ISO B |

2344 |

DAC |

|

1.2714 |

SKT 4 |

L6 |

|

SOMDIE |

W500 |

2714 |

2714 |

DM |

|

|

1.2367 |

- |

- |

|

QRO90 |

W303 |

2367 ISO B |

2367 |

- |

|

|

1.2767 |

- |

- |

|

Grane |

K600 |

X45CrNiMo4 |

- |

- |

|

|

|

|||||||||

|

Cold Work Steel |

1.1545 |

SK 4 |

W110 |

|

UHB20 |

K990 |

C105W1 |

1545 |

SK4 |

|

1.2436 |

- |

- |

|

Sverker 3 |

K107 |

X210CrW12 |

2436 |

- |

|

|

1.2510 |

SKS 3 |

O-1 |

|

DF2 |

K460 |

2510 |

2510 |

SGT |

|

|

1.2363 |

SKD 12 |

A2 |

|

XW40 |

K305 |

2363 |

2363 |

SCD |

|

|

1.2379 |

SKD 11 |

D2 |

|

XW41 |

K110 |

2379 ISO B |

2379 |

SLD2 |

|

|

1.2550 |

SKS 41 |

S1 |

|

M4 |

K455 |

2550 |

2550 |

- |

|

|

1.2842 |

- |

O-2 |

|

Aros |

K720 |

90MnCrV3 |

2842 |

- |

|