Stainless Steel Round Bars 304/316

S upper Super Company DMCC is a leading manufacturer of high-quality Stainless Steel Round Bars 304/316 in India. With years of experience in the industry.

With years of experience in the industry, we are committed to providing superior-quality products that meet our customers' diverse needs. Stainless Steel Round Bars 304/316 are alloys containing Nickel, Molybdenum, and Chromium, similar to grade. These pipes exhibit excellent toughness even at low temperatures. Additionally, the machinability of these pipes is noteworthy, as it results in the formation of long, gummy chips.

Shapes And Dimension Of SS Pipes

At Super Company DMCC, we manufacture and export Stainless Steel Round Bars 304/316 in different dimensions and shapes that include:

Stainless Steel Round Bar is one type of a product made in the stainless steel materials. There are different grades of stainless steels used in various industries. Stainless Steel Round Bars are used for their strength and corrosion resistance properties. Super Company DMCC is a leading Stainless Steel Round Bar manufacturer in India. All stainless steels contain chromium. The composition can vary and the chromium content varies as well. The more the chromium content, the high the corrosion resistance is.

Application Of SS Round Bar

Stainless Steel Round Bars 304/316 have various applications in various industries as listed below

Specification of SS Round Bar

| Stainless Steel Bar Length | 2 to 6 meters or 8 to 20 feet |

|---|---|

| SS Rod Chamfering | Available in 30, 45 & 60 degree thru fully automatic both-end chamfering machine |

| Ultrasonic Test of ASTM A276 Threaded Rod | As per ASTM A-388, EN 10308 (class 1 to 4), API 6A/ISO it is 100% tested

thru Digital Ultrasonic Flaw Detector, 10423:2003-PSL 3, MIL STD 2154, SEP 1920:1984 |

| SS Round Bar Size Tolerances | h11 |

| Tolerance of Cold Rolled SS Round Bar Length | Stock in special cut to length bar in tolerance – 0/+10mm (-0 +0.5 inch) |

| Surface Finish of Cold Rolled SS Bar | Cold drawn or Belt polished condition |

| Bar Heat Treatment | Annealed and Solution Annealed |

Chemical Composition of SS Round Bar

| ASTM Grade | Carbon | Manganese | Silicon | Sulfur | Phospherous | Chromium | Nickel | Molybdenum | Other |

| 304 | 0.08 max | 2.00 max | 0.75 max | 0.030 max | 0.045 max | 18.0-20.0 | 8.0 11.0 | - | - |

| 316 | 0.08 max | 2.00 max | 0.75 max | 0.030 max | 0.045 max | 16.0-18.0 | 10.0 14.0 | 2.0 3.0 | - |

| 317L | 0.035 max | 2.00 max | 0.75 max | 0.030 max | 0.045 max | 18.0-20.0 | 11.0 14.0 | 3.0 4.0 | - |

| 310 S | 0.08 max | 2.00 max | 1.5 max | 0.030 max | 0.045 max | 24.0-26.0 | 19.0 22.0 | 3.0 4.0 | - |

| 347 H | 0.04 0.10 | 2.00 max | 0.75 max | 0.030 max | 0.045 max | 17.0- 19.0 | 9.0 13.0 | - | 10C(Cb+Ta)<1.10% |

| 321 | 0.08 | 2.00 max | 0.75 max | 0.030 max | 0.045 max | 17.0-20.0 | 9.0 12.0 | - | 5C 0.70% |

Mechanical Properties of SS Round Bar

| Grade | Elongation | Density | Tensile Strength | Yield Strength (0.2%Offset) | Melting Point |

| SS 202 | 40 % | 8.0 g/cm3 | 515 MPa | 275 MPa | 1454 °C (2650 °F) |

| SS 303 | 50 % | 55% | Psi – 85,000 | Psi – 45,000 | Rb 180 |

| SS 304 | 40% | 8.0 g/cm3 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 1400 °C (2550 °F) |

| SS 304L | 40% | 8.0 g/cm3 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 1400 °C (2550 °F) |

| SS 316 | 35 % | 8.0 g/cm3 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 1454 °C (2650 °F) |

| SS 316L | 40 % | 8.0 g/cm3 | 485 Min | 170 Min. | 1400 °C (2550 °F) |

304/316 Stainless Steel Hex Bar

304/316 Stainless Steel Hex Bar is used in applications that require additional strength. The additional strength comes from the geometry of the hex bars. Stainless steels are in different types such as ferritic, austenitic, martensitic and duplex. The austenitic stainless steels are preferred for their strength and corrosion resistance properties. Super Company DMCC is a supplier of the 304/316 Stainless Steel Hex Bar in different sizes and grades. There are different grades of stainless steel with different specifications. These grades are mostly dependent on the chemical compositions.

316 Stainless Steel Hex Bar

The Stainless Steel Type 316 Hexagon Bar is made up of another grade, 316 stainless steel. It has molybdenum in addition to chromium and nickel to the composition.

304 Stainless Steel Hex Bar

The material is equally strong to the 304 grade and has a similar operating temperature limit of 870 degrees Celsius of the 304 grade as well. The difference comes in improved corrosion resistance to the 304 grade.

Application of Seamless Stainless Steel Hex Bar 304/316

Stainless Steel Hex Bar Specifications

| Dimensions | ASTM, ASME and API |

|---|---|

| Size | 3.17mm to 350mm dia |

| Length | 4 to 6meters, or as customer's requirements |

| Form | Hex Bar, Hexagonal Bar |

| Tolerance | DIN 671, ASTM A484 & as per customer's specific requirement. |

| Finish | Black, Bright, Cold drawn, Polish,Polished, Centreless Ground |

304/316 Stainless Steel Wire Rod

Super Company DMCC is one of the largest manufacturers of Stainless Steel Wire Rods in India. We produce impeccable quality wire rods in various grades and sizes at our state of the art manufacturing facility in Maharashtra, India, using the latest machines to provide the customers with utmost satisfaction. The biggest strength of Viraj Profiles Pvt. Ltd lies in the fact that we have in-house melting operations, which ensures that only the best quality wire rods are produced in our plant.

316 SS Wire Rod

Stainless steel is a low-cost and corrosion-resistant material with a high level of durability. It is ideal for both residential and marine applications. Not only is it durable and long-lasting with a perfect surface finish, but it also has excellent strength.

304 SS Wire Rod

Stainless Steel Wire Rods are increasingly present in household uses, interior decoration, automobile, aerospace, and medical applications which rely on their corrosion resistance, durability, and mechanical properties.

Application of SS Wire Rod

Stainless Steel Wire Rod have various applications in various industries as listed below

Specification of Stainless Steel Wire Rod

| Size Range | 5.5 mm – 26 mm (0.0217″ – 1.000″) |

|---|---|

| Wall Thickness | 0.5 mm to 6.00 mm |

| Tolerance | +/- 0.20mm |

| Length | upto 30 mtrs Wire Rods |

| Standards | ASTM, ASME, DIN, NF, JIS, EN, IOS |

| Packaging | On Spools DIN 125, DIN 160, DIN 200, DIN 250, DIN 355, BS 60, B10 |

| Temper | Annealed Wire Rods or Spring hard Wire Rods (stress relieved – optional), Hot Rolled Wire Rods, Pickled Wire Rods |

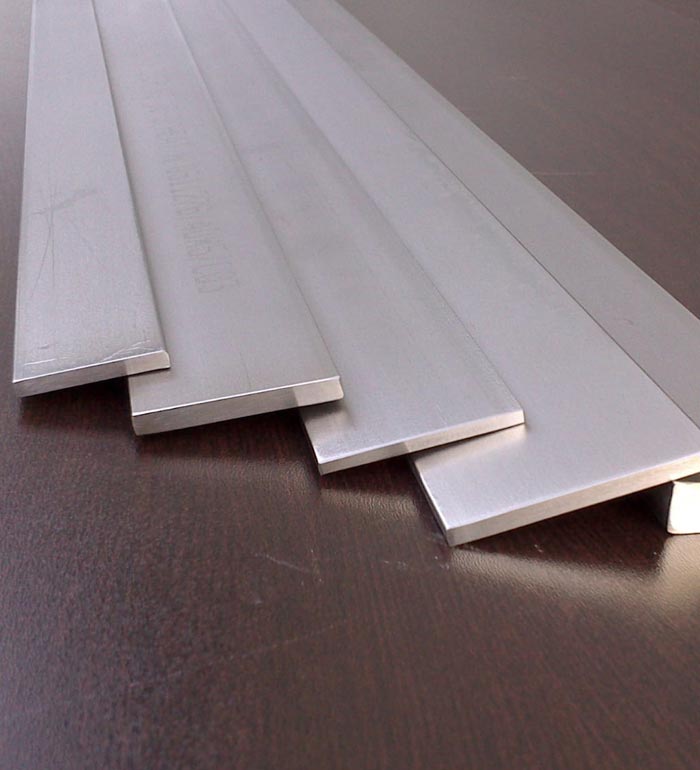

Stainless Steel Flat Bar

The Stainless Steel Flat Bars can be manufactured using different types of ss including ferritic, austenitic, martensitic and duplex. The material of the flat bars can vary according to its composition, however, the most used among them is the austenitic type. Depending on the steel grade with which the flat bars are made, it can be used in a wide range of applications.

Specification of Stainless Steel Wire Rod

| Specification | EN 10272, EN 10088-3 Grade 304/ 304L, 316/ 316L |

|---|---|

| Standard | API, ASME, SUS, DIN, EN, GB, UNS, ASTM, AISI |

| Sizes | 3mm to 800mm diameter |

| Length |

|

| Finish | Cold Drawn Turned, Bright Drawn, Polished, Rough Turned, Centreless Ground, Bright, Annealed, Smooth Turned, Peeled, Grinding, Black |

| Tolerances | H12, H11, K11, K12, H10, H8, H9, H13, K10, K9 |

| Surface Finish | 1D, HL, 8K, NO.4, 2D, NO.1, NO.3, 2B, BA |

| Production Method | Rolled / Forged |

| Characteristics |

|

| Value Added Services at Suraj Metal |

|

| Other available forms | Forging, Profiles, T-Bar, Rod, Hollow, Triangle, Channel, Threaded, Ingot, Rounds, Rectangle, Blocks, Billet, I/H, Half-Round, Angle, Precision-Ground |

| Port |

|

| Export to | Saudi Arabia, Peru, Italy, Malaysia, USA, Vietnam, Thailand, Egypt, Brazil, Ireland, Spain, Kuwait, Dubai, Singapore, Canada, Oman, Indonesia, Russia, Korea, Mexico, Canada, etc |

| Our Stainless Steel Flat Bar conforms to Standard ISO 15156/ NACE MR0175 | |

Features of SS Flat Bar

Stainless Steel Flat Bar have various applications in various industries as listed below

SS Flat Bar sizes

| METRIC STAINLESS STEEL FLAT BAR (mm) | IMPERIAL STAINLESS STEEL FLAT BAR | ||

|---|---|---|---|

| 8 X 5 | 50 X 12 mm | 3/8" x 1/8" | 1.1/2" x 1/2" |

| 12 X 3 | 50 X 20 mm | 1/2" x 1/8" | 1.1/2" x 3/4" |

| 12 X 6 | 50 X 25 mm | 1/2" x 3/16" | 1.1/2" x 1" |

| 12 X 10 | 50 X 40 mm | 1/2" x 1/4" | 1.3/4" x 1.1/4" |

| 15 X 3 | 60 X 3 mm | 5/8" x 5/16" | 2" x 1/2" |

| 15 X 5 | 60 X 5 mm | 3/4" x 3/8" | 2" x 5/8" |

| 15 X 6 | 60 X 6 mm | 1" x 3/16" | 2" x 3/4" |

| 15 X 10 | 60 X 8 mm | 1" x 1/4" | 2" x 1.1/2" |

| 16 X 8 | 60 X 10 mm | 1" x 5/16" | 2.1/2" x 3/8" |

| 20 X 3 | 60 X 12 mm | 1" x 1/2" | 2.1/2" x 1" |

| 20 X 5 | 60 X 15 mm | 1.1/4" x 1/8" | 2.1/2" x 1.1/4" |

| 20 X 6 | 65 X 5 mm | 1.1/4" x 1/4" | 3" x 1/4" |

| 20 X 8 | 65 X 6 mm | 1.1/4" x 5/16" | 3" x 1/2" |

| 20 X 10 | 65 X 8 mm | 1.1/4" x 3/8" | 3" x 3/4" |

| 20 X 12 | 65 X 10 mm | 1.1/4" x 3/4" | 3" x 1" |

| 25 X 3 | 65 X 12 mm | 1.1/4" x 1" | 4" x 3/4" |

| 25 X 4 | 65 X 15 mm | 1.1/2" x 3/16" | 4" x 5/8" |

| 25 X 5 | 70 X 10 mm | 1.1/2" x 1/4" | 4" x 1" |

| 25 X 6 | 75 X 3 mm | 1.1/2" x 3/8" | |

| 25 X 8 | 75 X 5 mm | ||

| 25 X 10 | 75 X 6 mm | ||

| 25 X 12 | 75 X 8 mm | ||

| 25 X 16 | 75 X 10 mm | ||

| 25 X 20 | 75 X 12 mm | ||

| 30 X 3 | 75 X 15 mm | ||

| 30 X 4 | 75 X 16 mm | ||

| 30 X 5 | 75 X 20 mm | ||

| 30 X 6 | 80 X 5 mm | ||

| 30 X 8 | 80 X 6 mm | ||

| 30 X 10 | 80 X 8 mm | ||

| 30 X 12 | 80 X 10 mm | ||

| 30 X 15 | 80 X 35 mm | ||

| 30 X 20 | 100 X 3 mm | ||

| 35 X 6 | 100 X 5 mm | ||

| 38 X 3 | 100 X 6 mm | ||

| 40 X 3 | 100 X 8 mm | ||

| 40 X 5 | 100 X 10 mm | ||

| 40 X 6 | 100 X 12 mm | ||

| 40 X 8 | 100 X 15 mm | ||

| 40 X 10 | 100 X 20 mm | ||

| 40 X 12 | 100 X 25 mm | ||

| 40 X 20 | 100 X 30 mm | ||

| 40 X 25 | 120 X 12 mm | ||

| 45 X 6 | 125 X 6 mm | ||

| 50 X 3 | 150 X 6 mm | ||

| 50 X 4 | 150 X 10 mm | ||

| 50 X 5 | 200 X 10 mm | ||

| 50 X 6 | 250 X 12 mm | ||

| 50 X 8 | 300 X 12 mm | ||

| 50 X 10 | |||

Chemical Properties

| Element | C | Cr | Mn | Ni | P | S | Si |

|---|---|---|---|---|---|---|---|

| SS 304 | 8.0 – 11.0 | 18.0 – 20.0 | 2.0 max | 8.0 – 11.0 | 0.045 max | 0.03 max | 1.0 max |

| SS 304L | 8.0 – 11.0 | 18.0 – 20.0 | 2.0 max | 8.0 – 12.0 | 0.045 max | 0.03 max | 1.0 max |

| SS 316 | 0.08 | 18.0 | 2.00 | 14.0 | 0.045 max | 0.03 max | 0.75 max |

| SS 316L | 0.08 | 18.0 | 2.00 | 14.0 | 0.045 max | 3.00 max | 0.10 max |

Mechanical Properties

| Element | Tensile Strength | Yield Strength | Elongation | Reduction in Area | Hardness |

|---|---|---|---|---|---|

| SS 304 | Psi – 85,000 | Psi – 45,000 | 50% | 55% | Rb 180 |

Stainless Steel Square Bar

The Stainless Steel Solid Square Bar of any grade of steel is used because of the strength of the bar. The square shape is geometrically stronger and can handle stress more than the round bars. So the material is used in pressure vessel applications and general corrosive services under specifications such as the ASTM A276 Stainless Steel 316 Square Bar.

Specification of Stainless Square Bar

| Grade List | All Grades |

|---|---|

| Bar Finishing | Bright, Polish, Square Round Bar |

| Otder Services | Machining, Centreless Grinding, Heat Treatment, Polish, Rolling, Anneling, Pickling, Forging, Cutting, Bending |

Composition Standard

| Element | C | Cr | Mn | Ni | P | S | Si |

|---|---|---|---|---|---|---|---|

| SS 304 | 8.0 – 11.0 | 18.0 – 20.0 | 2.0 max | 8.0 – 11.0 | 0.045 max | 0.03 max | 1.0 max |

| SS 304L | 8.0 – 11.0 | 18.0 – 20.0 | 2.0 max | 8.0 – 12.0 | 0.045 max | 0.03 max | 1.0 max |

| SS 316 | 0.08 | 18.0 | 2.00 | 14.0 | 0.045 max | 0.03 max | 0.75 max |

| SS 316L | 0.08 | 18.0 | 2.00 | 14.0 | 0.045 max | 3.00 max | 0.10 max |

Mechanical Properties

| Element | Tensile Strength | Yield Strength | Elongation | Reduction in Area | Hardness |

|---|---|---|---|---|---|

| SS 304 | Psi – 85,000 | Psi – 45,000 | 50% | 55% | Rb 180 |